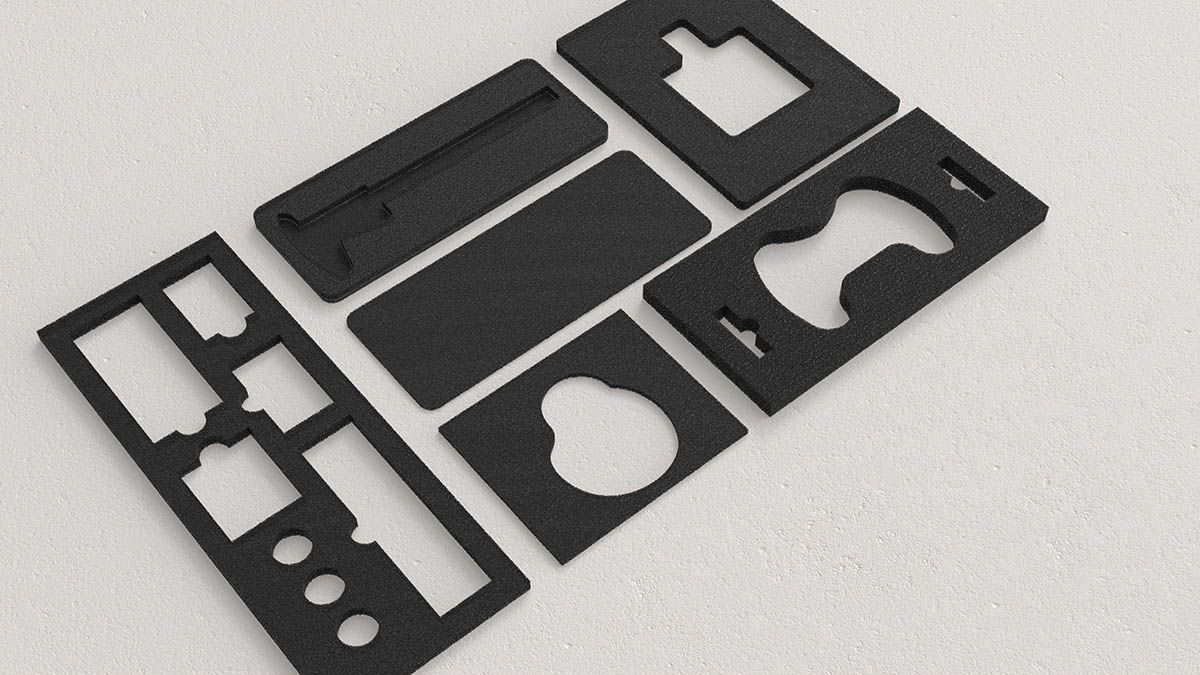

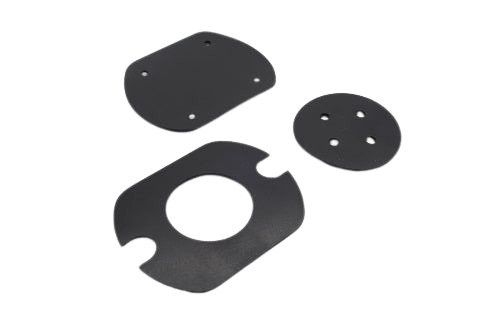

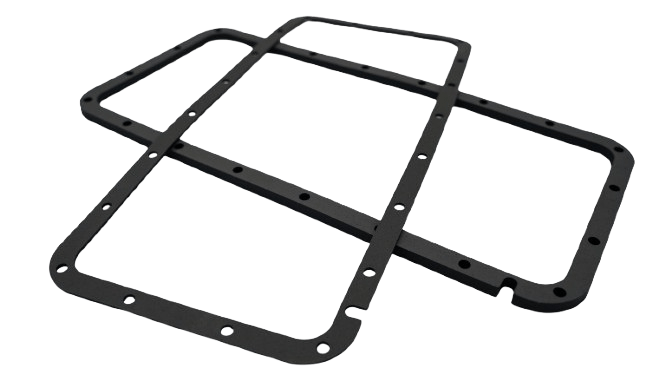

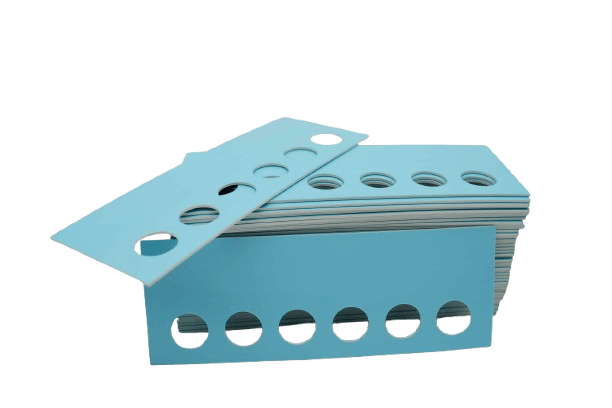

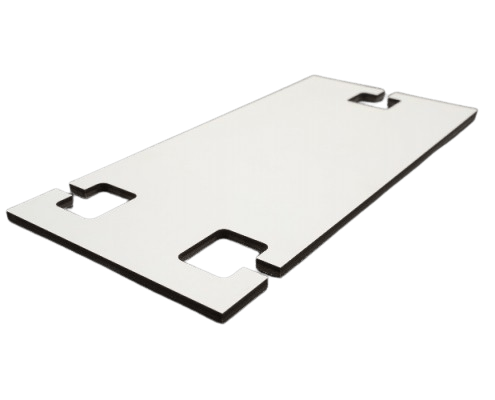

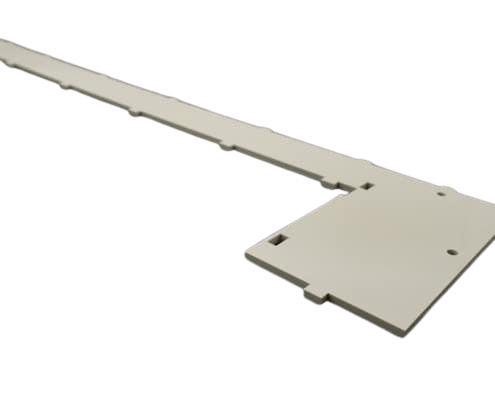

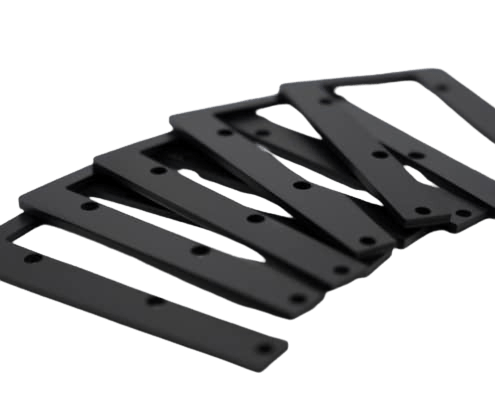

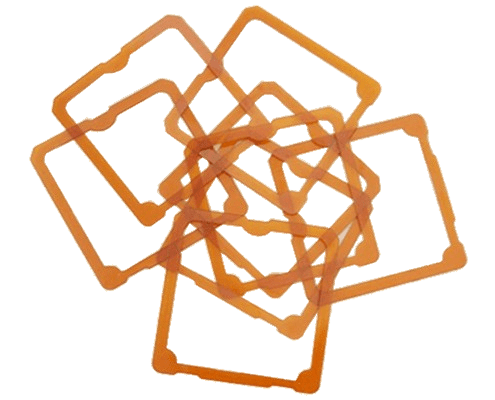

EPDM Foam (Ethylene Propylene Diene Monomer Sponge Rubber)

Other

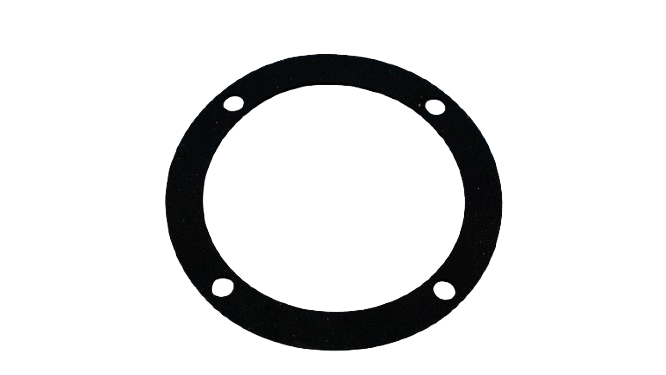

EPDM Foam is a synthetic closed-cell sponge rubber made from ethylene propylene diene monomer. This material is known for its excellent weather resistance, UV stability, and durability, making it ideal for demanding environments. Thanks to its elastic properties and ability to retain shape after compression, EPDM Foam is widely used for sealing and insulation applications.

Well-known trade names include Keltan®, Nordel®, and Vistalon®.

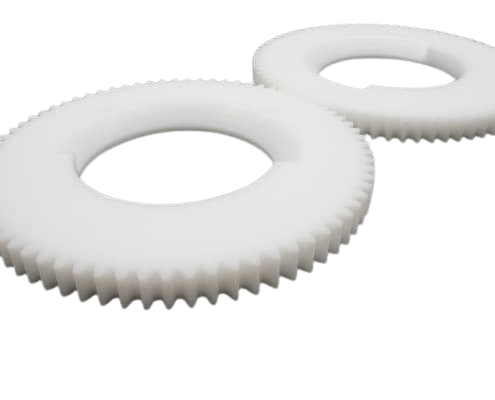

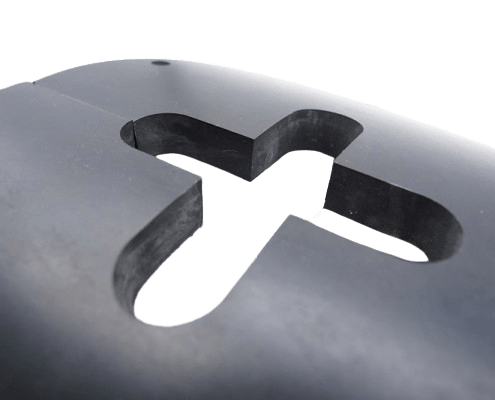

- Laser cutting

- Milling