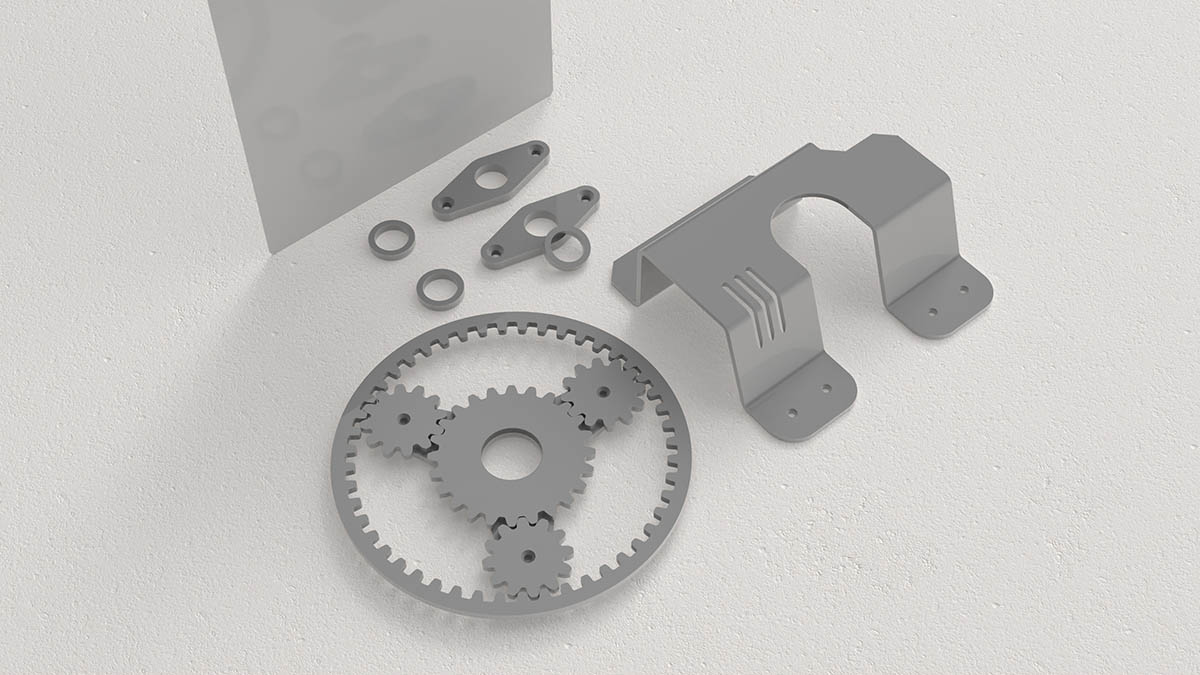

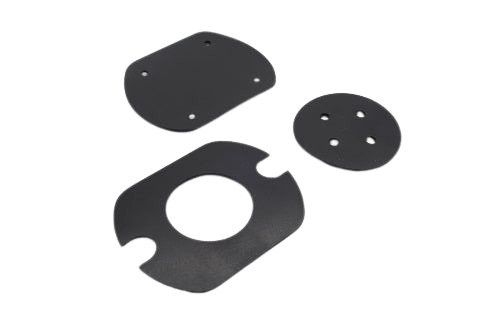

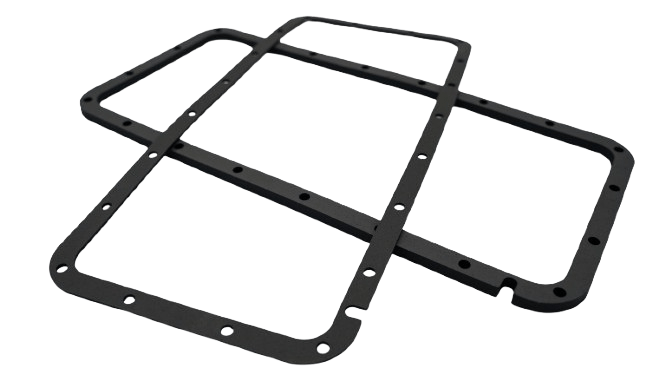

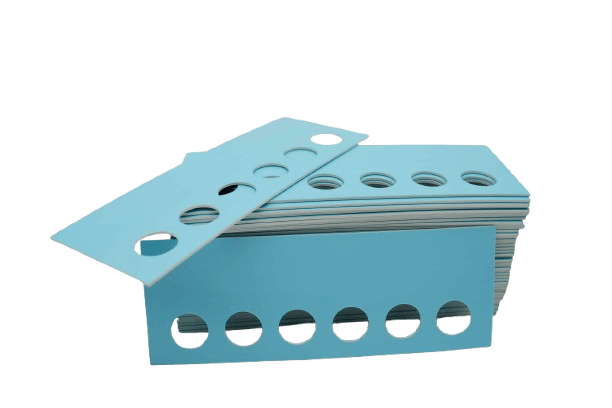

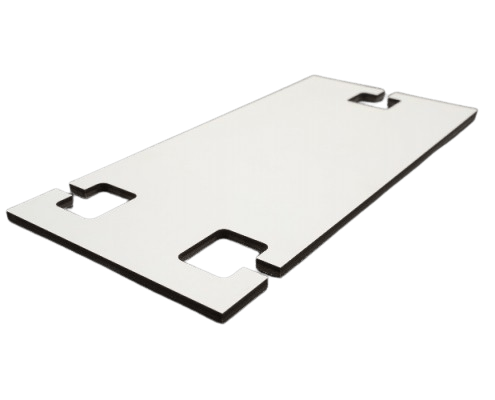

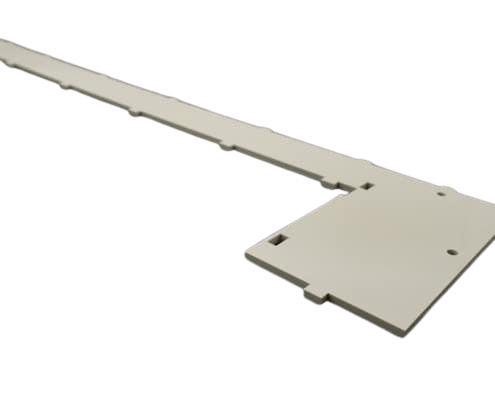

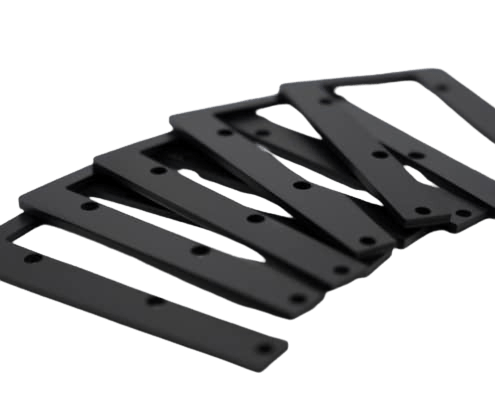

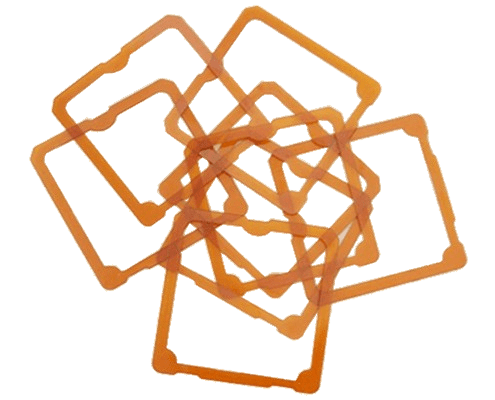

PPS (Polyphenylene Sulfide)

Plastic

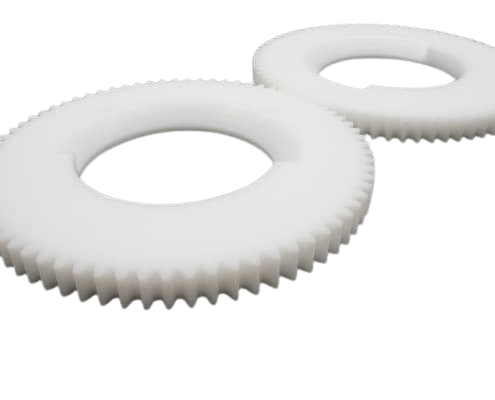

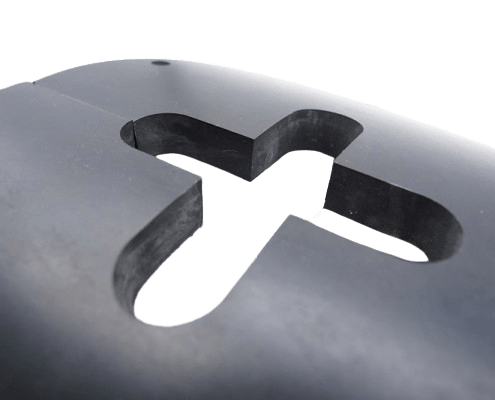

PPS is a high-performance engineering plastic known for its excellent chemical resistance, high temperature resistance, and mechanical strength. The material retains its shape and properties even under extreme conditions, making it ideal for applications in aerospace, automotive, and electronics. PPS is also flame retardant and highly dimensionally stable.

Well-known trade names for PPS include Ryton®, Fortron®, Tecatron®, and Torlon® (in blends). These grades are often chosen for critical parts that are exposed to heat and aggressive chemicals for extended periods.

- Laser cutting

- Milling