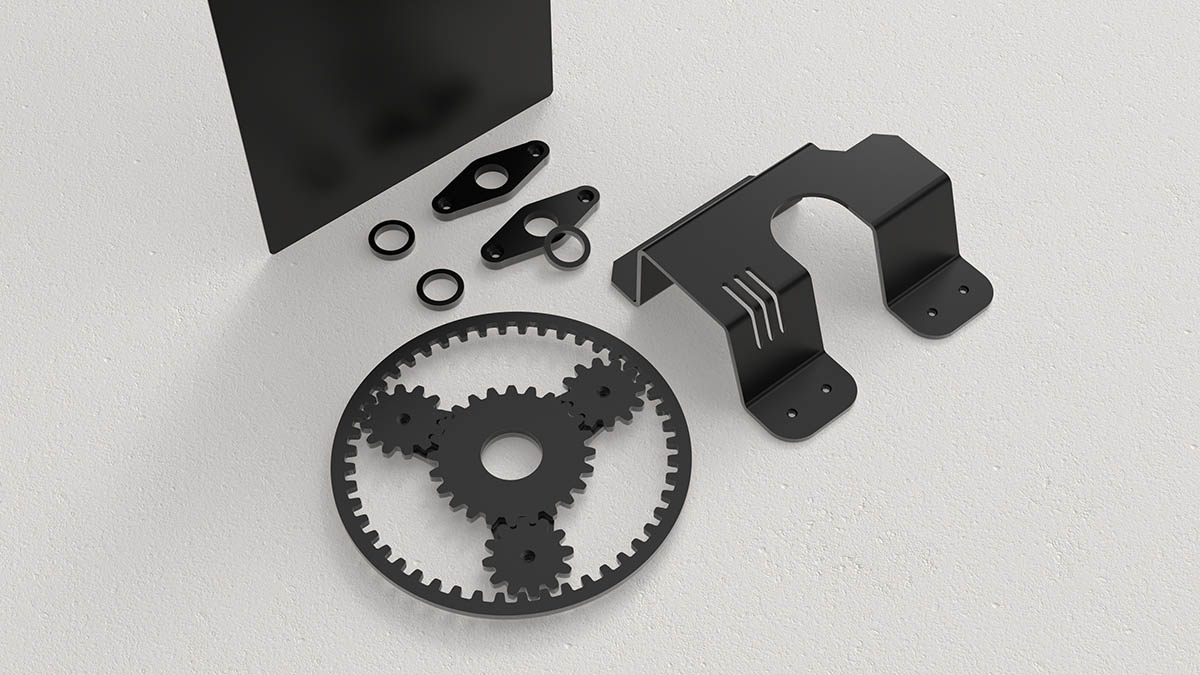

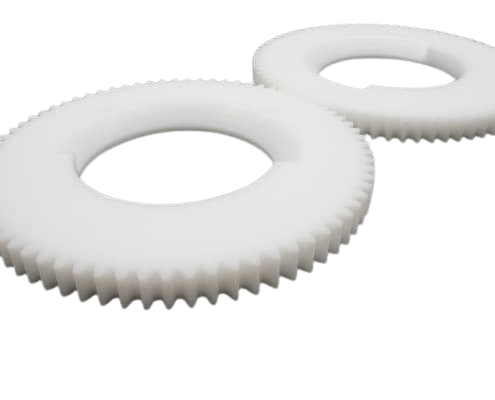

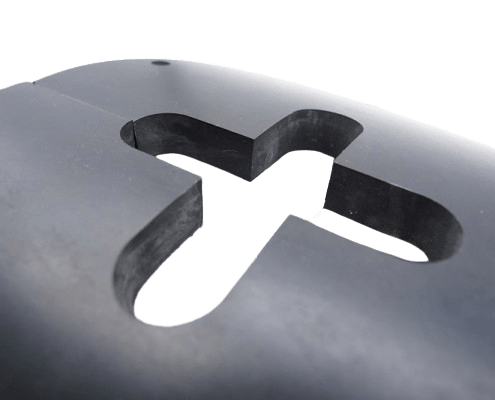

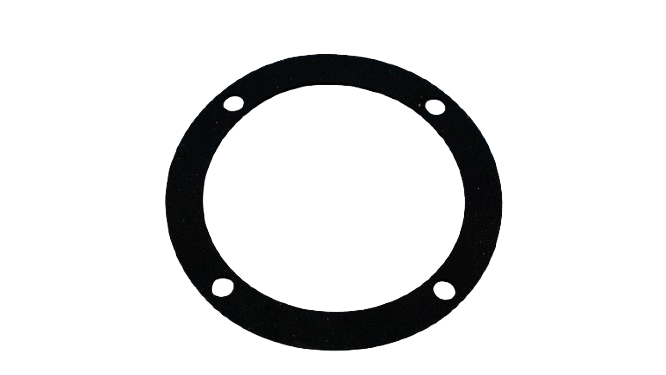

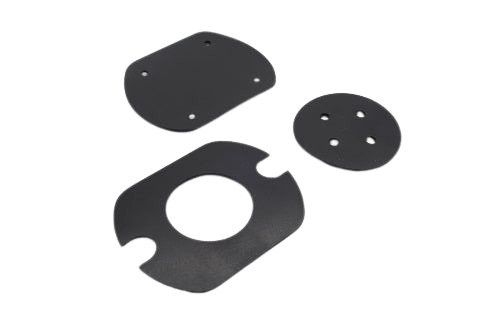

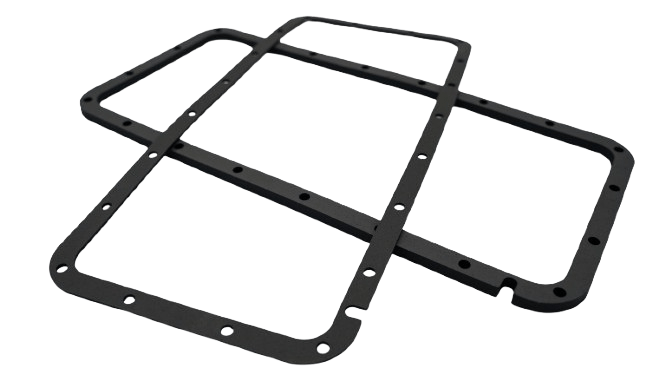

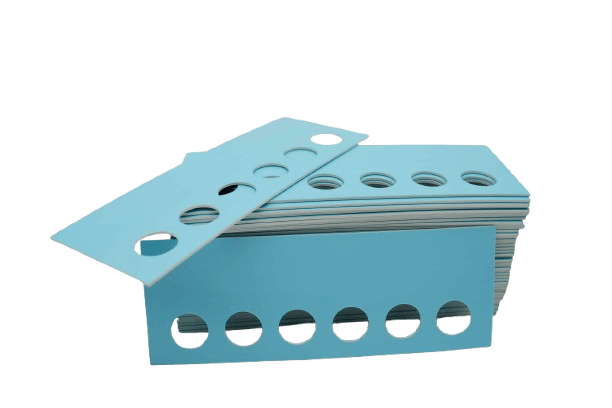

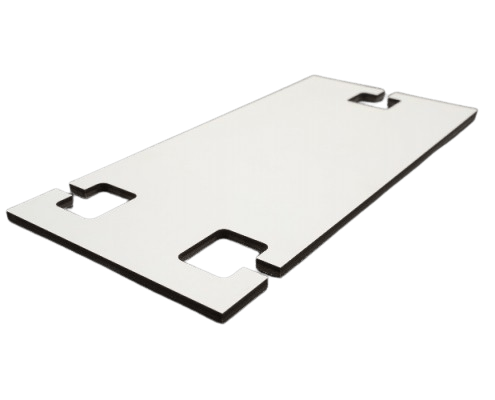

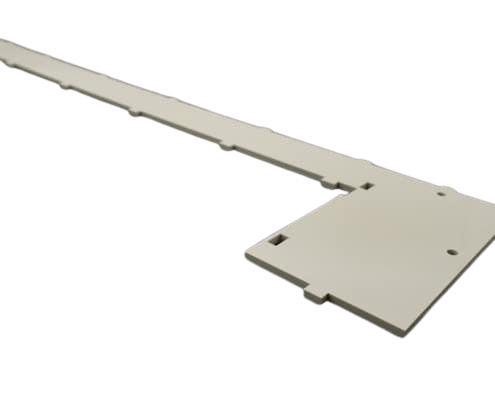

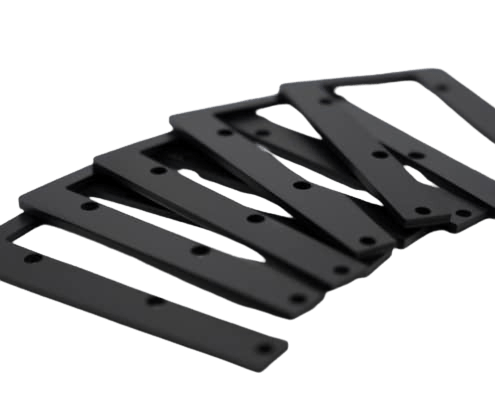

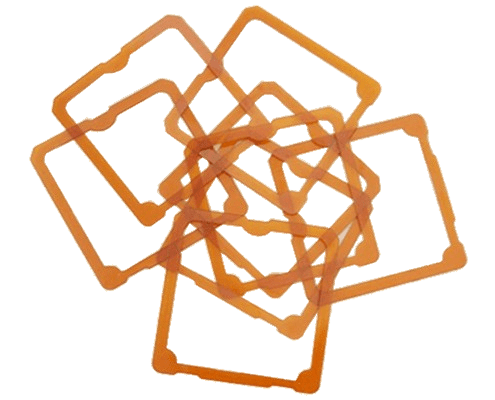

POM (Polyoxymethylene)

Plastic

POM, better known as polyacetal or Delrin®, is a high-performance engineering plastic prized for its exceptional mechanical strength, dimensional stability, and low friction coefficient. Thanks to these qualities, POM is ideal for applications where precision and wear resistance are critical.

Well-known trade names for POM include Delrin®, Hostaform®, and Ultraform®. These materials are renowned for their reliability and are widely used across various industrial sectors.

- Laser cutting

- Milling