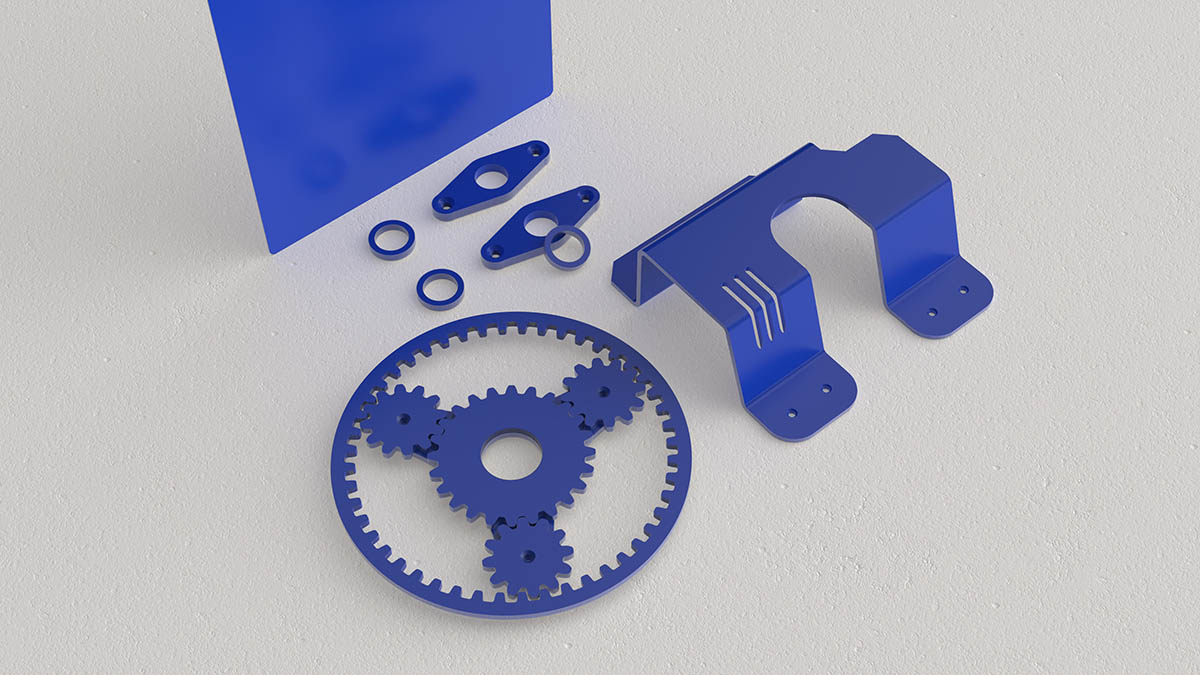

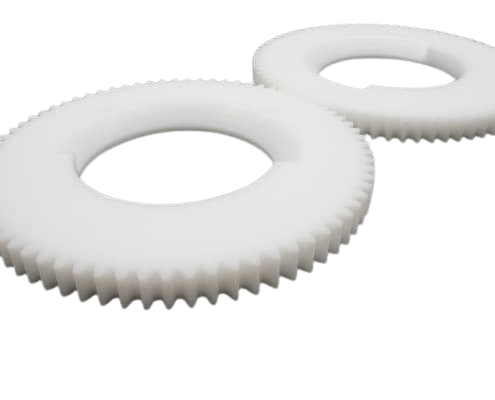

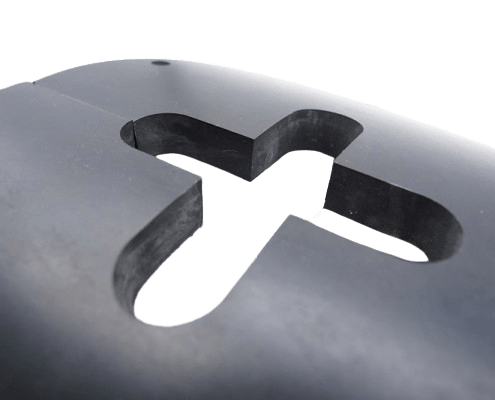

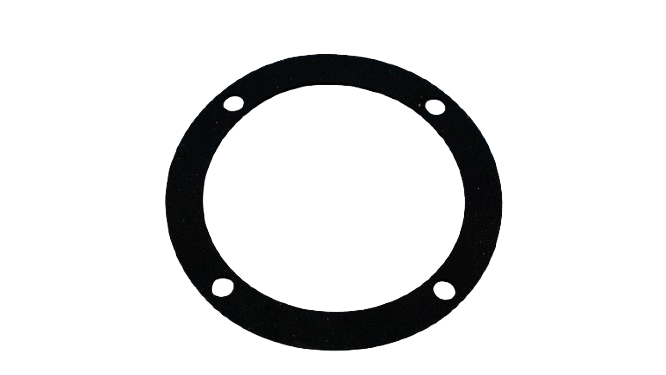

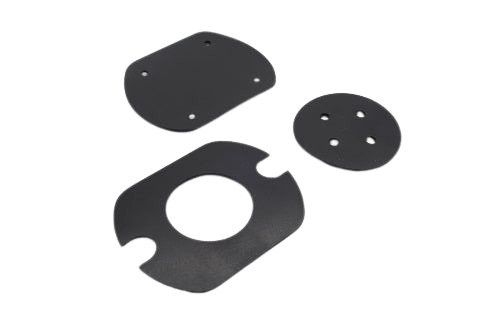

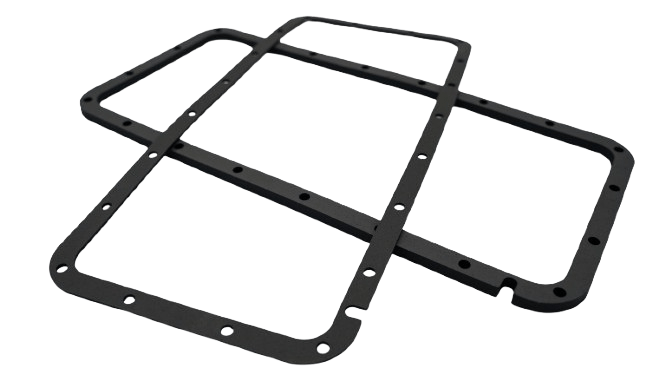

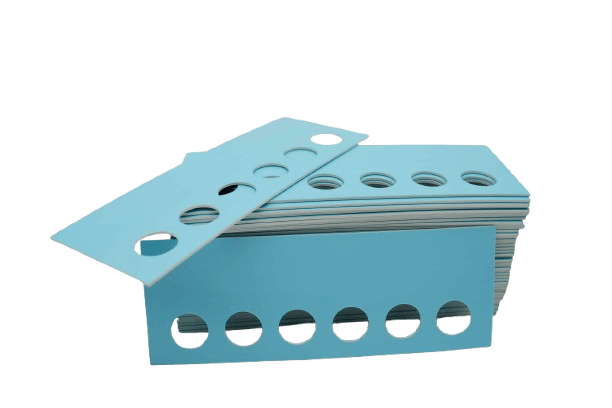

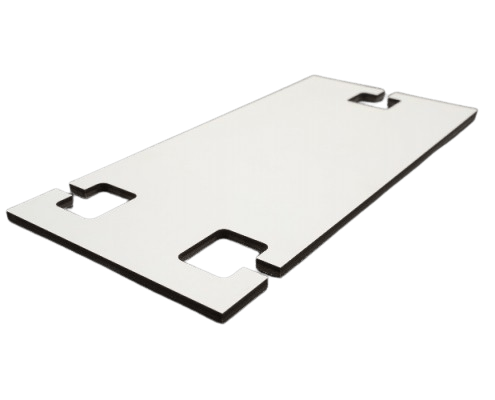

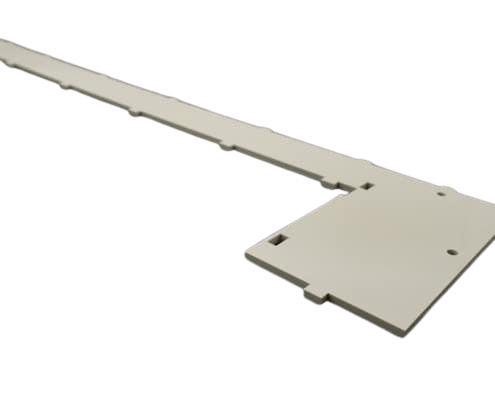

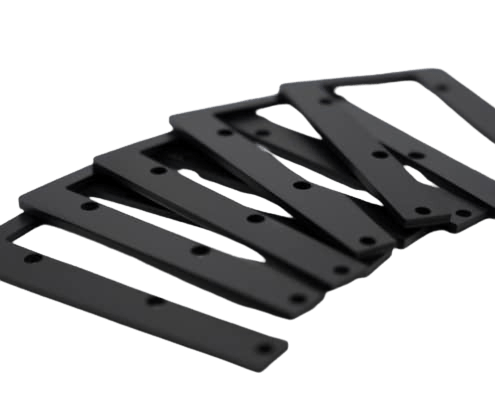

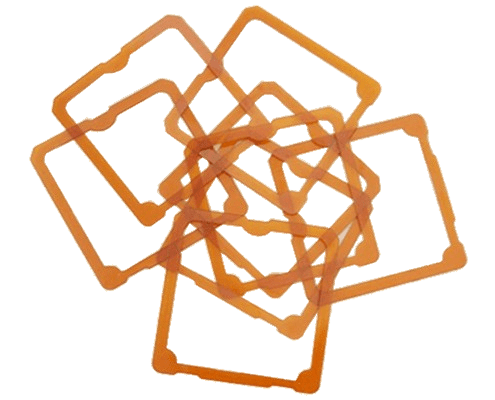

HMPE-500 (High Molecular Polyethylene)

Plastic

HMPE-500, also known as UHMW-PE 500, is an abrasion-resistant and tough plastic with excellent sliding properties. This material is chemically resistant, shock-absorbing, and food-safe, making it ideal for applications in the food industry, transport engineering, and machinery. HMPE-500 combines high impact resistance with a low coefficient of friction, even at low temperatures.

Well-known trade names for HMPE-500 include Tivar® 1000, Polystone® M, and Hostalen® GUR. These grades are widely used in wear-resistant and sliding components.

- Laser cutting

- Milling