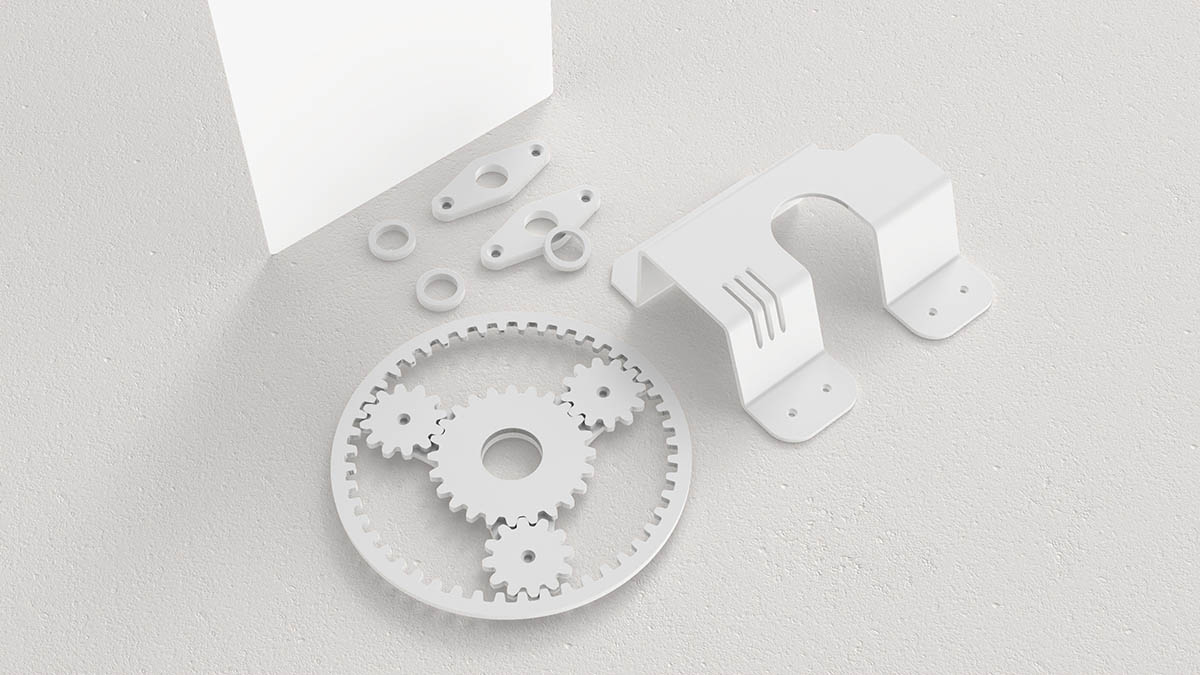

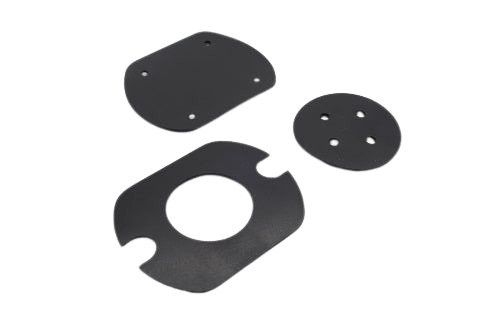

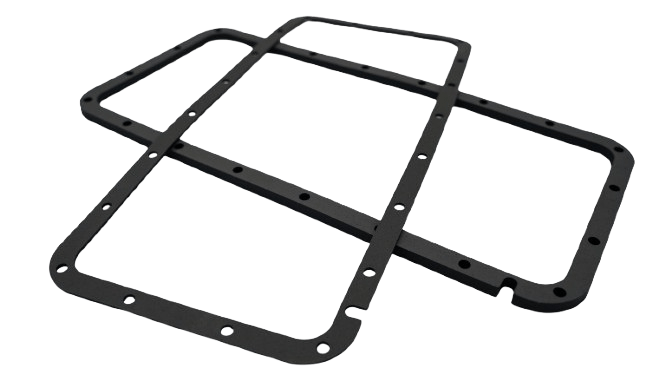

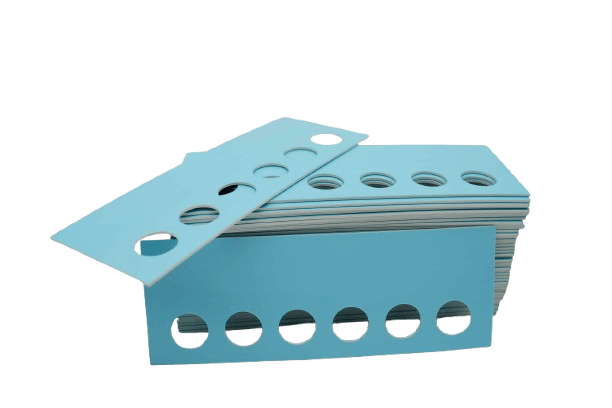

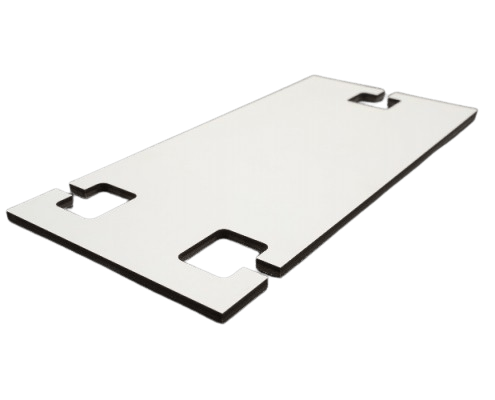

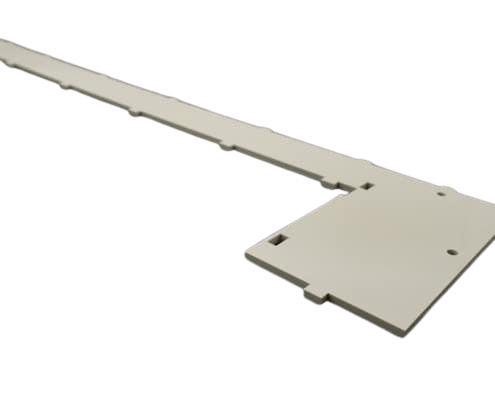

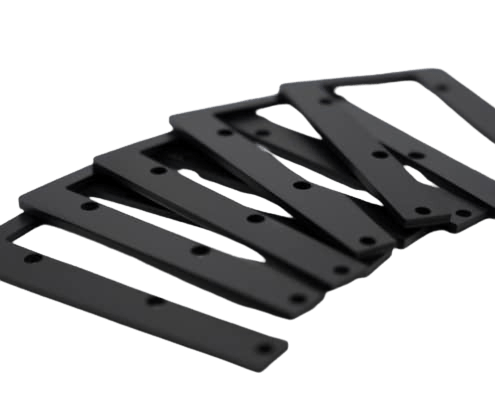

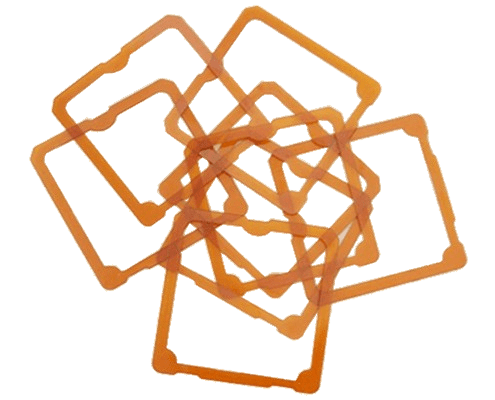

ABS (Acrylonitrile-Butadiene-Styrene)

Plastic

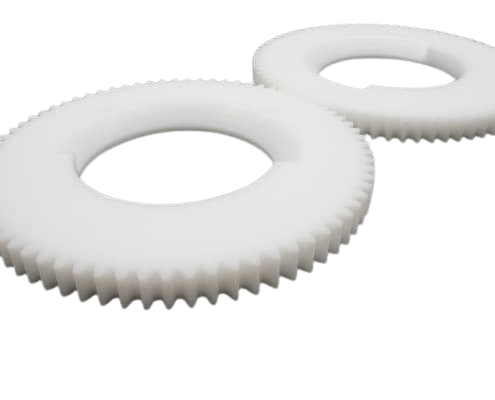

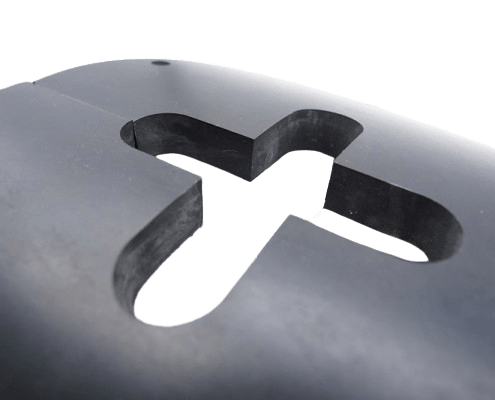

ABS is a versatile engineering plastic known for its good impact resistance, stiffness, and formability. The material is easy to machine, glue, weld, and thermoform. ABS combines the best properties of three polymers, making it a widely used solution in machinery, automotive, electronics, and consumer products.

Well-known trade names for ABS include Terluran®, Novodur®, ABSOLAC®, and Cycolac®. These grades are often chosen for structural and functional parts with high design freedom.

- Laser cutting

- Milling